Surface inspection systems

Monday 13th February, 2017Shelton Vision has been a Surface Inspection specialist for over thirty years, providing unique automated inspection solutions through our WebSPECTOR machine vision system. Ideal for all sectors which require process optimisation and quality control from machine input to output. This type of machine vision adoption results in better quality, higher productivity and less waste.

High speed integrated vision systems

Our automated surface inspection systems rely on a unified approach with our customers, enabling us to implement defect classification. Those defects which are most important to our customers can be graded allowing more insignificant issues to pass by without the flow of production being halted. These deviations are stored within the inspection system and help guide future decisions.

Defects which can be detected include, but are not limited to the following:

- Stains

- Solvent spots

- Misprints

- Cracks

- Non-woven black spots

- Contamination yarn

- Dyeing stop

- Foreign fibre

- Hair

- Impressions

Here you can see some of the many surface inspection defects caught by our bespoke machine vision system:

Shining a light on defects

By using a combination of line scan cameras and carefully placed lighting, Shelton Vision can detect the smallest of defects across a range of complex surfaces.

Our case study about high resolution inspection of contact lenses is a great example of our work with challenging surfaces.

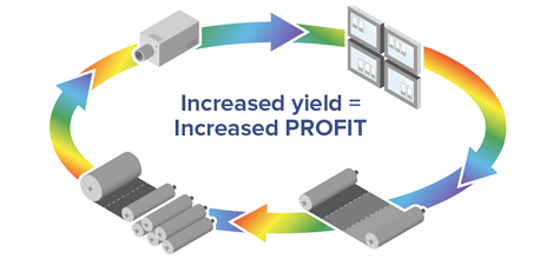

Automated surface inspection systems allow for a greater ROI

Shelton Visions’ bespoke vision inspection system means a variety of fault types are well within the range of our machine vision system. If you would like to get in touch to discuss how we could help provide the optimum yield for your batch, then please call 0116 279 0920 or alternatively complete our contact form.