Consistent high resolution inspection of contact lenses from optical area to rim

When molded contact lenses need to be checked at high speed for manufacturing defects, such as cracks, chips, flashing, shrinkage and several other potential issues.

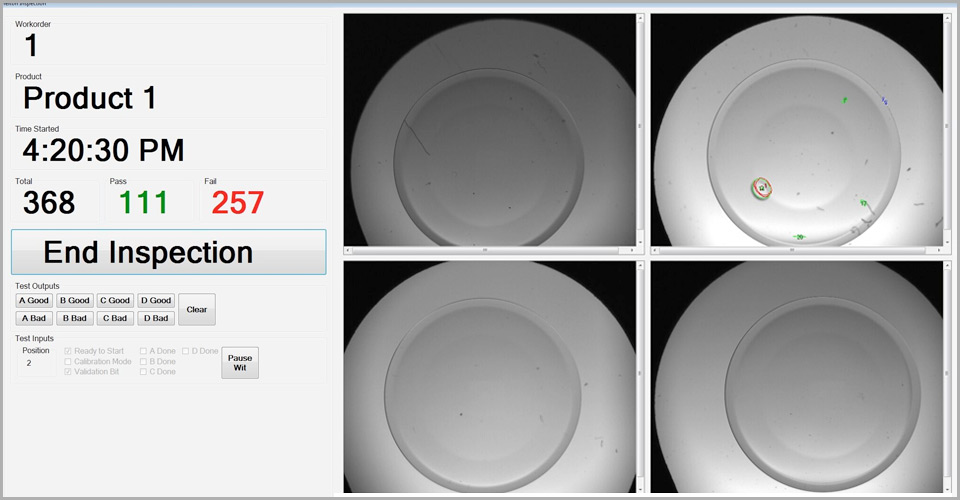

To detect the full range of defects requires three different lighting conditions and images obtained and processed for each within the cycle time of manufacture.

The Problem…

Previously existing contact lens inspection systems had the following drawbacks;

They were low resolution and so could not detect very small defects that are required to be reported.

It was not possible to apply high resolution imaging throughout the depth of the lens due to depth of field restrictions, therefore not all defects were detected.

Only one light source was used so not all defect types were automatically detected. This required manual sample inspection.

Contact lens manufacturers did not have 100% product inspection and the market demand for higher quality was increasing.

The Solution…

Shelton Vision were asked to produce a contact lens high resolution inspection system that could inspect at high resolution throughout the lens depth and detect all defects that may occur without any manual sampling checks.

A system was created in less than 2 months that enabled up to 150 high resolution images to be acquired throughout the depth of the lens (ie from the optical area down to the rim) with 3 lighting conditions employed for each camera position within less than 2 seconds cycle time. The lighting was multiplexed and synchronised to the camera trigger and the lens control system.

This arrangement enabled every defect type to be automatically detected from anywhere on the lens at a resolution of several times higher than previous systems.

The Outcome…

A system was built for operation on a delensing machine which was integrated into the delensing machine operation cycle time and installed successfully.

Shelton Vision applied for a patent on some unique features developed and have established closer ties to their contact lens machinery manufacturing partner to develop similar ground breaking products in the field of automation.

Testimonial

“The development by Shelton Vision has enabled us to achieve more consistent and higher accuracy inspection throughout the lens height. This means our overall inspection is more precise and we can avoid manual sampling for defect types that our other older vision systems are unable to see” – Business owner