Machine Vision Solutions

About Machine Vision

Machine Vision enables computers to ‘see’ and to detect subtle irregularities in products at speeds and consistency far exceeding human vision capability. A machine vision system uses one or more sets of cameras to capture images for analysis.

For manufacturers that require 24 hour operation, manual grading and inspection isn’t a complete solution to reducing customer returns and rejections. With production speeds sometimes exceeding 100m/min high speed inspection can only be achieved through machine vision technology.

Vision inspection systems offer near 100% accuracy, and with many human inspectors needed to keep up with high volume production of critical products, machine vision integration make sense financially. Industrial vision systems also perform these functions more efficiently with not only greater speed, but with better reliability and precision, compared to human inspection.

A perfect solution would be an inspector that never sleeps, applies consistent inspection criteria at the same speed as production. This is where machine vision quality inspection technology steps in.

Vision Inspection Systems

Machine vision inspection systems vary widely. At one end of the scale you have those systems that require a lot of manual interaction. At the higher end vision systems that are automated in operation and do not require an ‘operator’.

The Shelton WebSPECTOR surface inspection system can be fitted to an existing process or purpose built as a stand-alone high-speed machine vision inspection system.

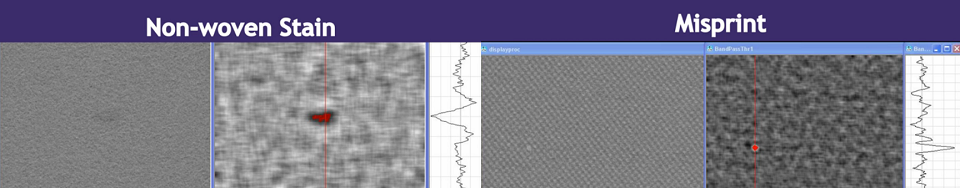

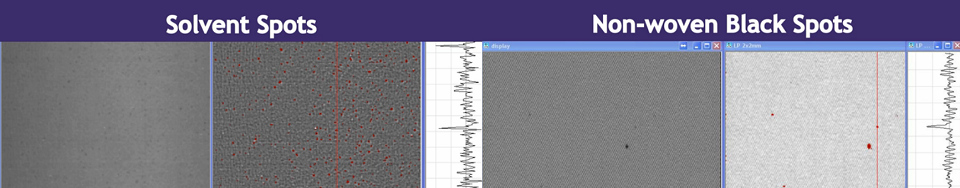

As defects are detected, an image is stored along with all the identifying data. This allows WebSPECTOR to classify the defect by type, as well as apply a severity grade, in real time prior to physically marking the web in line with the defect.

The defect map reduces waste and increases yield by providing the most cost effective cutting plan. The optimised plan can be then implemented precisely under the system control and split into small rolls for shipment and end use.

Shelton’s quality inspection system can grade defects on a case by case basis. Grading allows filtering of inconsequential defects of a certain type or severity while recording real defects.

Unlike most vision systems on the market, WebSPECTOR integrates advanced machine vision technologies and algorithms that can detect all visible defects.

Industrial vision systems produce and define a clear distinction between defects of differing causes that may appear visually similar.

An example of classification in operation would be for the system to understand where a piece of fluff is loose on the surface of a fabric as opposed to a piece of fluff that has been entangled within the fabric construction. The former has no consequence, whereas the latter is a defect.

Line Scan Cameras

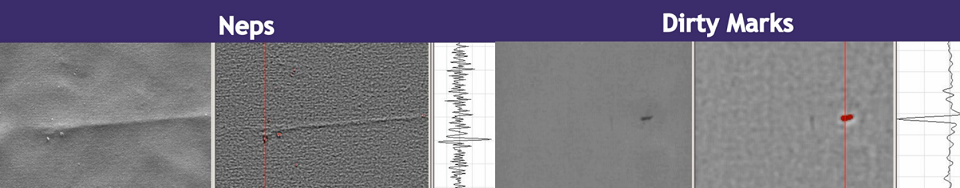

For enhanced surface inspection WebSPECTOR uses multiple line scan cameras in multiple planes of view, with different methods of illumination to enable a full range of defect detection.

Shelton vision systems use machine vision based software developed with multi layer programming. The advanced globally available hardware provides a robust platform that enables a high level of sustained system performance.

Industrial Cameras and Lighting Angles

We use a range of lighting and camera configurations to help identify the widest range of defect detection.

The configurations considered most useful are; “diffuse top light”, “back light”, “low angle shadow” and “low-angle side shadow”. These have been shown to be the most useful configurations when dealing with textiles.

Machine Vision Solutions for Industries

Every industry relies on innovative technologies to help improve overall performance and productivity. Machine vision technologies minimise waste and manual labour whilst increasing yields, a solution that would benefit any company. Here are some key industries that would directly benefit from vision system integration:

- Medical – Trace any deviation from the source and audit the results.

- Aerospace – A reliable inspection solution enables companies within the Aerospace industry to comply with tough industry standards and regulations.

- Automotive – A vision inspection system allows a high standard of quality control which is essential to the competitive automotive industry. Missed defects in automotive interiors for example, can affect the value and overall appeal of a vehicle.

- Textiles – Reduce waste and increase profits for the textile industry by detecting faults at the beginning of the production process.

- Non-Woven – Quality inspection systems produce real time, reliable and traceable data. This not only identifies defects but separates them from one another.

- Composites –Shelton Vision have experience in inspecting 3D components for the composite industry.

Machine Vision Applications

The benefits of automatic vision inspection systems are:

- Exceed customer specifications and expectations

- Further your company’s reputation by not shipping sub-standard products, encouraging future business

- Achieve process improvement by monitoring any increase in the number of faults and take remedial action in good time

- Achieve increased raw material utilisation and yield whilst reducing overall waste

Automatic vision inspection systems are no longer seen as niche for special high-end products. Machine vision technology is becoming very much expected among the textiles and fabric industry. Not only do companies need quality inspection systems to comply with ever higher standards, they also need to be ahead of their competitors in terms of profitability and cost.