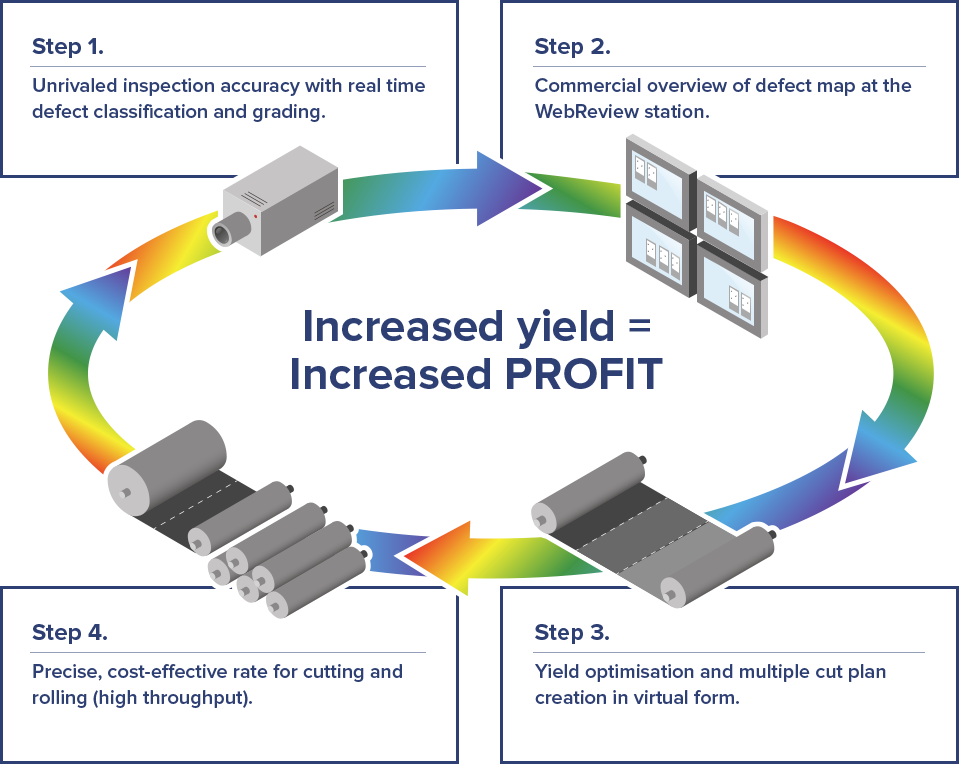

WebSPECTOR: The 4 steps to profit creation

Shelton Vision produce a comprehensive machine vision system made up of 4 components that together deliver an automatic solution to achieve the ultimate inspection and small roll making department that ensures maximum profit from each batch, virtually eliminates customer claims and provides consistent data for process improvement.

This system includes a number of modules that perform specific tasks; CBIGS, WebCORDER, WebREVIEW, WebTRAINER and WebOPTIMISER

Step 1: Unrivalled inspection accuracy

The first step in the process is for the system to provide consistently correct defect detection, classification and grading results, even on the most demanding of fabrics. Read more

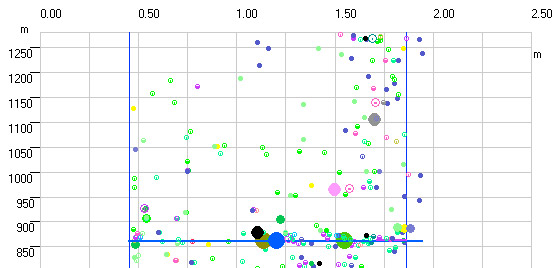

Step 2: Commercial overview of the defect map

The final commercial decision is always made by a person, guided by the vision system results.

In order to provide the optimum commercial result the classified and graded defect images can be quickly scanned by a QC technician to make any commercial interventions.

To enable thousands of metres of results to be checked in minutes the process is driven by a wizard and defects can be viewed in the context of full web width. Read more

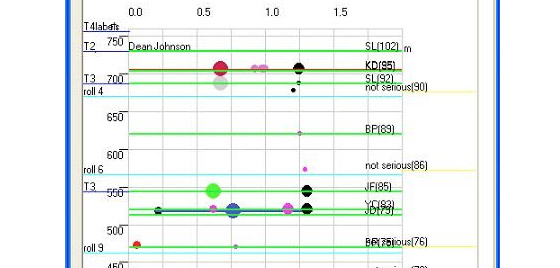

Step 3: Optimised multiple cut plan creation in virtual form

The WebOptimiser enables multiple cut plan options to be performed on a virtual batch to determine the optimum cutting plan for any inspected batch.

The optimisation process is usually biased towards providing the highest yield, but by operating multiple cut plans simultaneously with the Shelton WebOptimiser other options can be considered such as a bias towards lower defect rate. Read more

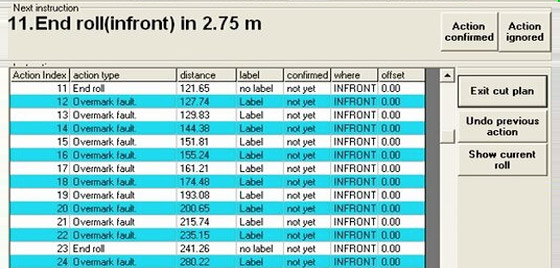

Step 4: Precise, cost-effective cutting and rolling

Once the optimised cutting plan has been calculated by the WebOptimiser it is vital that the data is transferred to the rolling, cutting and packing process and that the process is accurately controlled to enable the calculated plan to be performed accurately.

The WebViewer enables continuous synchronisation of the cut plan and fabric on the cutting machines by mathematical calculation of stretch factor between the electronic defect map, the cut plan and the physical position of the fabric to ensure precise cutting to achieve the desired output. Read more

In conclusion - the big benefits are...

- Percentage increase in yield provides an increase in profit equivalent to the same percentage of turnover.

- Reduction in manpower, lead time for supply, customer claims, waste and landfill costs

- Eliminate airfreight resupply costs.

- Improved quality analysis reports and for process improvement and supplier relations.

- Retain existing and attract new customers.

Next Step - Contact Us

See how our inspections systems can benefit your business call us today on (+44) 116 279 0920 or use our online form.