Automated optical inspection (AOI)

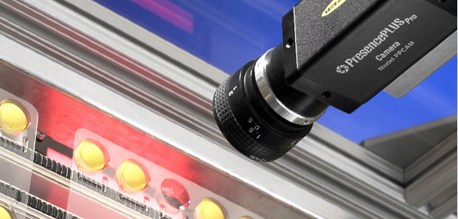

Automated optical inspection systems

Shelton Vision provides the fabric and textile industries with Automated Optical Inspection (AOI) systems and solutions.

The significant advantage offered by all proven computer inspection systems lies in the consistency of operation and applied standard, allied to the speed at which they

can operate. They give the user access to inspection data in real time at a point in the production cycle that can minimise costs, waste and customer rejections by lowering overall defect rates.

A range of different machine vision processes and application are applied, increasing accuracy and improved quality through out the production line.

Automated defect detection

The WebSpector textile inspection system tackles demanding defect finding tasks where the feature being looked for differs from the normal appearance of the fabric, which the system has previous assessed.

The automatic optical inspection system runs a large number of algorithms simultaneously at high speed to target certain features such as vertical, horizontal and diagonal straight and curved lines as well as spot and area defects. These algorithms cover the range of textile defects when combined with the specialised lighting planes provided with the system.

Many of the algorithms are unique and specifically created for detection of subtle defects found in textiles.

When defects are detected the system can automatically place a label on the fabric edge in line with the defect, as well as record images of each defect, the position within the defect map as well as storing a complete video of the total fabric surface.

Although a defect may be seen by more than one plane of view (set of cameras and associated lighting) the system combines the results to report the correct number of defects.

Real-time classification and grading of textile defects

Once a defect has been detected the system then applies classification and grading rules in real time for each defect candidate detected. The rules are based on the system learning the defect types from a large number of mathematical properties per defect image to name the defect and applying user determined grading boundaries to determine how to sentence the defect (eg. Apply label or filter out as not serious – acceptance/rejection of the feature as a defect).

The range of defects are diverse and subtle in nature, so the system has been designed to have the tools and capability to make accurate and consistent decisions on defect sentencing, which is not possible with human inspection.

The automation of classification and grading allows a faster and more consistent Review process where a final commercial decision can be made regarding the final defect map.

Detectable defect grading

The defect type and severity grade is recorded in real time, allowing images to be stored and the corresponding data can be used to adapt the cutting plan. Here are some, but not all, of the defects that can be detected:

- Abrasion

- Black Spot

- Broken Pick

- Coating Line

- Colour Variation

- Contamination

- Contamination Yarn

- Delamination

- Dirty Marks

- Dyeing stop

- Foreign Fibre

- Fused Fibre

- Hair

- Impression

- Longitudinal crease mark

- Misprint

- Mixed Yarn

- Neps

- Non-woven black spots

- Non-woven contamination

- Non-woven contamination

- Non-woven defects

- Non-woven stain

- Impression

- Paper contamination

- Pigment line

- Reed mark

- Repeating weft defects

- Shade change

- Snag

Surface inspection defect detection

In this video you can see how the defect detection system uses a signal to noise (S/N) ratio to detect the defect. The video displays each defect with its corresponding graph. The large peak indicates a fault compared to the much smaller peaks of the background texture. The ratio between fault peak and largest background peak gives the signal to noise ratio (S/N).

Benefits of AOI

The benefits from automating textile inspection reach from fabric production and processing through to part cutting and garment making to retail and product industrial product assembly and manufacture.

The range of benefits include a reduction in manpower and labour costs, increased throughput per person/machine, increased inspection reporting accuracy and consistency, reduction/elimination of returns/customer claims, avoiding costly airfreight re supply, avoiding on-site inspection costs, enabling automation of optimised cut plan application for yield improvements.