Review defects in real-time

Monday 8th April, 2019

In today’s highly competitive global market being able to review defects digitally will help you to make key decisions in real-time.

The virtual cutting plan generated by Shelton’s WebSPECTOR system helps you get the most from each run. The commercial review of the defects takes place at the WebREVIEW station by the operator.

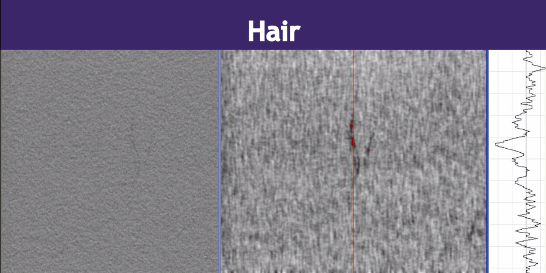

The WebREVIEW station consists of a bank of four monitors that display thumbnails of all the classified and graded defects that have been detected by a machine vision camera in a particular work order.

Defect grading

Grading defects allow you to differentiate between different types of defects that appear visually similar. This filtering process ignores inconsequential defects of a certain type whilst recording more severe examples and classification provides a clear distinction between defects of differing causes.

Each type of defect is listed and the operator can select to display defect images by type and can expand the image to show the defect in full fabric width context.

The WebREVIEW feature allows a high-speed commercial overview of the machine vision camera inspection results, in preparation for creating a cutting plan for the batch or quality control reports.

Virtual defect map

A defect map is a virtual form of the fabric batch that has been inspected, pre-planned cutting solutions can be applied to the map in its virtual form to calculate the optimum outcome.

Being able to calculate the optimum cutting plan for any batch using machine vision technology allows you to produce the maximum yield from each run.

Reduce defects with Shelton’s automated vision systems

Shelton Visions’ bespoke automatic inspection system helps increase throughput and production capacity. If you would like to get in touch to discuss how Shelton could help, then please call 0116 279 0920 or alternatively complete our contact form.