Defect mapping solution

Monday 25th March, 2019Shelton’s machine vision inspection systems have a real and measurable impact on your bottom line. Our high-speed cutting plan optimisation helps reduce cost and improves your overall yield.

The WebOptimiser vision system enables multiple cut plan creation options to be performed on a virtual batch to determine the optimum cutting plan for any inspected batch.

Visualisation of cutting plan

The optimisation process is usually biased towards providing the highest yield, but by operating multiple cut plans simultaneously with the Shelton WebOptimiser other options can be considered such as a bias towards lower defect rate.

Textile cutting plan optimisation

The WebOptimiser part of the Shelton Vision solution has the cutting requirements for each customer preloaded, such as minimum and maximum roll length, the allowable number of defects, or demerit points per roll, which defects have to be cut out or which defects can remain etc.

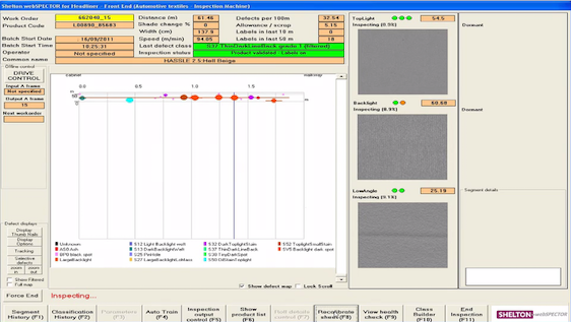

Detailed defect map

The defect map automatically grades and classifies defects depending on their severity. The defect map is a virtual form of the fabric batch that has been inspected and pre-planned cutting solutions can be applied to the map in its virtual form to calculate the optimum outcome.

Automated inspection can significantly increase yield compared to manual inspection. As a business, you will become more efficient, allowing resources to be used elsewhere within the business.

The reason yield is important is that for every fraction of a percent the yield is improved means the same fraction of a percent of turnover added to the bottom line.

Contact us to discuss our defect mapping solutions

To learn more about how our defect mapping solution could increase your yield call Shelton Vision today on 0116 279 0920. Alternatively, complete our online contact form.