Defect classification

Thursday 23rd March, 2017

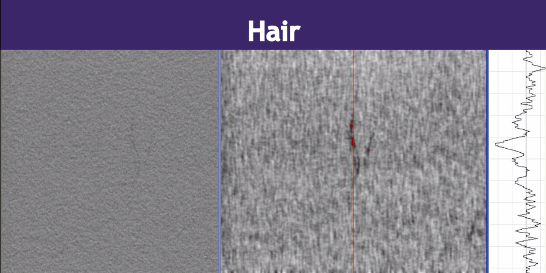

Shelton’s machine vision solutions allow our customers to identify and classify defects. We build tailor made machine vision applications that identify defects and segment them into bespoke classifications. Image segmentation refers to the process of dividing image into groups with similar characteristics.

The following steps are carried out prior to the defect classification:

- Line scan cameras acquire the image

- Image enhancement and segmentation

- Defect identification and classification

Machine-driven classification vs Manual inspection

Traditionally the identification of defects is done manually by human inspectors, over time with fatigue and human error a certain amount of defects would be missed. The automation of the visual inspection process enables both high quality products and high-speed production.

Benefits of defect classification:

- Differentiate between different types of defects that appear visually similar

- Improve productivity by only stopping the production line for serious defects

- Grade the quality of materials received from your suppliers

- Build trust with greater quality control

- Meet and exceed global market pressures that put higher demand on quality

Machine vision technology is becoming increasingly common across a range of industries, such as pharmaceutical companies and the automotive industry. Not only do companies need quality inspection systems to comply with ever higher standards, they also need to be ahead of their competitors.

Automated defect detection

Get in touch with Shelton today to find out how defect detection and classification could help your business. Please get in touch by completing our online contact form or call 0116 279 0920.