Our in house defect analysis process

Monday 4th April, 2016Understanding our customer’s individual requirements ensures a unique system specification is set. At the very beginning of the process we request defect samples from our customers. We use these samples to classify each type of defect that needs to be detected.

This due diligence at the start of the process reduces time and costs while the system is being configured for that customer. The joint process pays dividends going forward because both parties are on the same page. The transparency in performance capability helps builds trust from the very beginning.

The WebSPECTOR system can be adjusted to a range of fabric types with different characteristics and also borderline defects that need to be detected.

We use different lighting arrangements and cameras to best suit the needs of the customer. The potential of different fabrics being used in the future will not cause a problem, since the technology works by normalising all images to a standard piece of fabric.

Defect analysis using SNR

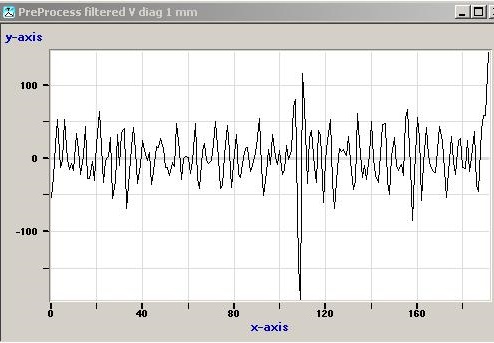

For each fault, one or two texture removal techniques are employed to remove texture information that cannot be the fault. The level of fault separation from the texture is then given by the signal to noise level. The “noise” being the remaining natural texture, and the “signal” being the strength of the fault. This then tells us if this kind of fault will be detected reliably in production conditions.

We look for a minimum signal to noise ratio of background noise (normal surface texture signal) compared to the signal generated by the defect after applying image processing techniques.

In this example the top image shows the fault. This image is processed and the graph then shows a peak due the misread fault compared to the much smaller peaks of the background texture. The ratio between fault peak and largest background peak gives the signal to noise ratio (S/N). SNR compares the level of a desired signal to the level of background noise. The graph shown is related to the vertical columns of the image:

The fault was captured by using a vertical camera with top light illumination.

Fault detection and analysis

WebSPECTOR’s fault detection and analysis techniques mean a variety of fault types are well within the range of this machine vision technology. If you would like to get in touch to discuss how we could help provide the optimum yield for your batch, then please complete a contact form or call Shelton Vision on 0116 279 0920.

Follow Shelton Vision on Twitter