Garment quality control

Monday 24th April, 2017We enable our customers to increase sales and build trust with their customers. It is important for every company to maintain a high level of quality in everything that they produce.

In the garment industry, garment quality control is practised right from the initial stage of sourcing raw materials to the stage of a final finished garment.

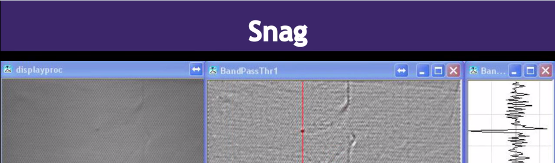

Shelton Vision provides machine vision solutions that help detect and reduce the number of defects within the production process.

Shelton’s WebSPECTOR is a quality control system that is made up of four components, all contribute to an automated optical inspection system that achieves maximum inspection ensuring maximum profit from each batch.

The cost of quality?

- More waste means less profit

- Poor quality will damage your chances of winning new business

- Consistent defects can ruin relationships with your customers or stop a brand launch in its tracks

Commercial advantages to effective quality control

- Staying ahead of the competition

- Less waste leads to more margin on the bottom line

- Happy customers and clients

- Savings from a reduction in waste can be invested back into your business

- Once the inspection system is set up and running man power can be used elsewhere

Garment defects

The following examples can be classed as defects within garments and textiles:

- Different shades within the same garment

- Fabric defects

- Exposed notches

- Loose or hanging threads

- Pulled or loose yarn

- Holes

- Defective stitches

- Stains

Quality control standards

The national regulatory quality certification and international quality Programmes like ISO 9000 series lay down the broad quality parameters based on which companies maintain the export quality in the garment and apparel industry.

Here are some of the main considerations for garment manufacturers and exporters:

- Overall look of the garment

- Right formation of the garment

- Feel and fall of the garment

- Physical properties

- Colour fastness of the garment

- Finishing properties

- Presentation of the final produced garment

Automated surface inspection systems for Garment quality control

Shelton Visions’ bespoke machine vision applications identify faults and use defect maps to help grade issues. If you would like to get in touch to discuss how we could help provide the optimum yield for your batch, then please call 0116 279 0920 or alternatively complete our contact form.