Automotive fabric producer protects customers, reduces claims and increases throughput

Fabric used in automotive interiors is vital in enhancing image and aesthetic appeal to car buyers.

Significant value is added when formed into headliner, seating, sun shade or other components.

The materials and manufacturing processes mean imperfections occur in the fabric. It is vital these defects are detected and flagged, or removed before further value is added in the next stage of manufacture.

Traditionally defect detection has been performed by people inspecting fabric running over an illuminated inspection table.

The Problem

Manual inspection of automotive fabric is challenging because a person is unable to apply a consistent level of inspection all over the fabric at the required throughput speed, with all the lighting conditions needed to see every type of defect. This means defects are missed and get delivered to the customer and may have additional value added before the defects are noticed. When this occurs the customer generally makes a claim on the fabric supplier, not only for the lost fabric, but for the added value and associated costs. Therefore the claims can be high and disproportionate to the value of the fabric.

The Solution

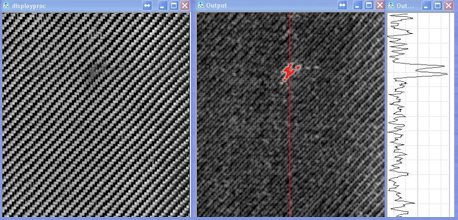

To solve this problem one UK based automotive fabric producer invested in a WebSpector inspection system automatic textile inspection system from Shelton Vision. The WebSpector system is designed to incorporate all the necessary lighting conditions to enable detection of the full range of defects that might occur and has state of the art cameras and imaging software to pick out the most subtle defects needed to be detected and report them on an electronic defect detection map, with classified and graded defect images.

To add to the benefit of claim reduction the system was designed to operate at speeds over 10 times faster than human inspection which also increased throughput.

Shelton carried out detailed defect sample testing to determine the system specification and to ensure that the desired outcome was achieved.

The Outcome

The automotive fabric producer increased capacity by increasing throughput per person in the packing department by 50% whilst also consistently operating at record low ppm’s which provides a saving of several million pounds per year from customer quality claims.

They have been able to use the data provided by the WebSpector system to improve upstream processes and determine root causes of defect issues.

They are able to use their inspection system as a marketing tool to retain and reassure existing customers, as well as attract new ones.

Shelton Vision provide ongoing support as part of a comprehensive customer are package.

Project statistic

The automotive fabric producer increased capacity by increasing throughput per person in the packing department by 50%