Industrial cameras for the textile industry

Wednesday 18th May, 2016Advanced automatic vision inspection systems, such as the Shelton WebSPECTOR, are based on continuously applying unique detection algorithms to the images of the product being conveyed past the vision camera, the results of which are tempered by a previously calculated reference of the normal textural appearance of the product.

Industrial cameras image capturing

The multiple sets of industrial cameras in the imaging system are triggered by an encoder on the fabric transport machine to capture images of the fabric under a variety of associated lighting conditions.

The cameras employed are Teledyne Dalsa Linea CMOS GigE based line scan cameras. Linea uses Teledyne DALSA’s own advanced CMOS line scan sensors with high QE and low noise for better image quality.

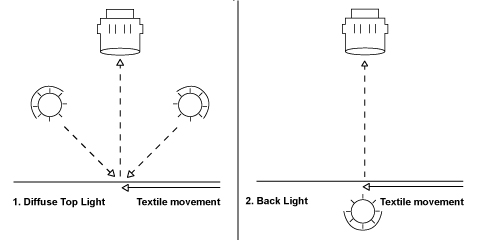

The illumination is from LED light sources positioned at various angles in relation to the fabric, mainly concentrated on the face side, but sometimes on both the face and rear side.

Vision cameras in practice

Often the defects are self-colour without any contrast to the surrounding fabric and may be as a result of the surface being snagged, or from an impression during winding. To detect unacceptable raised features in the fabric, an illumination technique was developed to enable reliable detection for point raised defects, such as snags, or plucks as well as for impressions.

Line scan cameras mounted above the fabric capture images of the material as it is illuminated by an LED light source positioned at a shallow angle of incidence to the fabric. Although virtually all of the light is reflected out of the field of view of the camera when surface features are present, the light is scattered and enters the camera to reveal the raised features or impressions.

Scanned images processed by WebSpector

Once the industrial cameras have acquired the line scan images of the fabric, the images are transferred to a PC where the images are processed by a set of WebSpector image processing and feature detection modules. These modules determine the defect type, severity and whether parts of a defect image need to be ‘joined’ to other parts of similar defects in the same location to accurately report the total length of a long running, or repeating defect.

Inspection camera variations

Typically, one camera can handle a product (fabric) width of 100 cm. In the case of a wide product, multiple cameras are installed, and the application of multiple cameras allows the full coverage of widths up to a practically unlimited dimension.

Both practical inspection speed and practical inspection width per camera ultimately depend on the resolution, i.e. the smallest defect size that has to be detected. The smaller the defect size to be detected, the more pixels are required per unit area, and the narrower the product width that can be covered by a single camera.

Next step

Advanced vision inspection systems can be a benefit to a range of industries, please get in touch via our contact us page or call (+44) 116 279 0920 for a confidential chat around your specific needs.