Apparel value chain

Thursday 11th May, 2017

Shelton can help you introduce an automated inspection system to your production line, which will help reduce costs within the apparel value chain, by reducing unnecessary cost looping within the process.

The aim of our machine vision systems is to reduce the following targets:

- Cost looping – cost looping occurs when a cost is unnecessarily incurred more than once for the desired result. The longer the loop the more costly the process, which impacts your overall profit margins.

- Duplication – fabric examination and colour checking is duplicated between producer and garment maker

- Waste – inaccurate cutting plans increase fabric waste and time is wasted by not producing the correct output at the first attempt

- Energy – re-shipping faulty products and the high number of exam machines

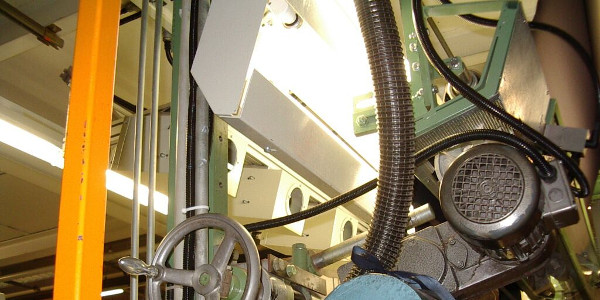

Automated machine vision solutions

- Keep unavoidable loops short and in the same plant, detecting faults at the earliest possible point

- Avoid duplication by examining once and sharing validated results

- Sheltons automated inspection systems will provide an optimised cutting plan that will minimise waste

- Invest in one automated system that will provide accurate and validated inspection data

Apparel value chain cost reduction and ROI

- Cost of scrapping and resupply

- Cost of reshipping

- Cost of customer claims

- Cost of wasted fabric

- Value of increased capacity and reduced labour

- Value of increased customer relations

Inspection systems for the garment and apparel industry

If you require an automated inspection system that will reduce the amount of waste within your production process please get in touch for a confidential discussion around your business requirements, call 0116 279 0920 or alternatively complete our contact form.